High Temperature Resistant PEEK Precision Parts

Brand Name: Sun-Yee Precision

Certification: ISO90001,ISO13485

Minimum Order Quantity: One piece

Payment Terms: L/C, T/T

Place of Origin: GuangDong, China

Price: Quotation as required

- Description

- Inquiry

Description

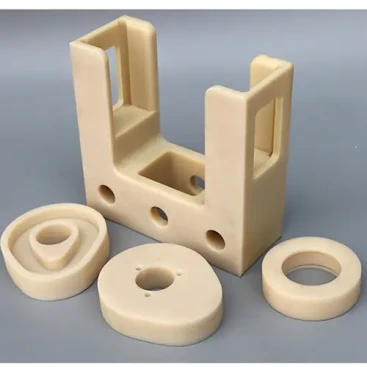

High Temperature Resistant PEEK Precision Parts Introduction

Product: High Temperature Resistant PEEK Precision Parts

Machining method: CNC processing, engraving processing, laser cutting, lathe milling machine

Tolerance:+/-0.005 – 0.01mm(Custonize avaiable)

Surface Roughness:Ra0.2 – Ra3.2(Custonize avaiable)

Materials Avaiable:Such as aluminum, copper, stainless steel, iron, PEEK, PE, PVC, ABS, etc.

Surface treatment:Smooth,sandblasting,anodizing,electroplating,zinc plating, etc.

MOQ:1 pc

Drawing Format:2D/(PDF/CAD);3D(IGES/STEP)

Our Service:OEM&ODM CNC machining,as per customer’s requirement

Equipment:CNC Machining Center,CNC lathe,CNC turning,milling

PEEK material

PEEK is a kind of special engineering plastics with high temperature resistance, self-lubricating, easy processing and high mechanical strength and other excellent performance. Can be manufactured and processed into a variety of mechanical parts. Such as automotive gears, oil sieve, gearshift starter disk, aircraft engine parts, automatic washing machine rotor, medical equipment parts and so on.

Areas of application:

1. Aerospace:

PEEK materials were first used in aerospace applications, replacing aluminum and other metal materials in the manufacture of various aircraft components.

2. Automotive

The growth of PEEK in the automotive industry is mainly due to the automotive industry’s demand for lightweight components. PEEK’s good friction resistance and mechanical properties of the key components can replace metal, becoming an important material to achieve automotive lightweighting, PEEK can be used to manufacture the inner cover of the engine, bearings, brakes and air conditioning systems in the ABS valves, gaskets, clutch rings and other components. PEEK can also be used to manufacture turbo compressors, pumps, valves, wires and cables, power seat gears, standard parts, etc.

3. Electronic information industry

The emergence of smart phones, tablet PCs and other consumer electronics accelerates the development of electronic components towards integration and miniaturization, but the performance of the existing materials used to manufacture electronic components is increasingly difficult to meet the relevant development needs.

PEEK provides an ideal solution for the selection of related materials, with its excellent chemical and physical properties and excellent processing performance, PEEK can be used for the manufacture of aluminum capacitor shells, thus realizing lead-free soldering. PEEK can be used to manufacture aluminum capacitor housings, thus realizing lead-free soldering of electronic components.

In addition, PEEK can also be in the field of electronic information for the manufacture of thin film antennas, back pressure regulator film liner, thin film switch panels and inductors, cell phone microphone spacer and other electronic components.

At the same time, due to excellent sound and durability, PEEK film is widely in the manufacture of high-performance audio and smart phone speaker diaphragm.

4. Energy sector

In the industrial, energy and high-end manufacturing industries, PEEK is widely as an insulating material in seals, bearings, flexible printed circuit boards, carrier tapes, ring tapes and other key components due to its corrosion resistance and good mechanical properties. Taking bearings as an example, PEEK is self-lubricating and does not require the addition of lubricant compared to metal bearings. This advantage makes the application of PEEK bearings in production lines involving chemical reactions promising, as it fundamentally avoids the situation of lubricant dripping off during long-term use of bearings and metal flaking off into the reaction liquid after wear.

5. Medical and Healthcare Industry

PEEK is closer to the rigidity of human bones than metal materials. And PEEK is a non-metallic material, so there is no artifacts in postoperative CT and MRI, which does not affect the subsequent diagnosis of medical images. PEEK has the characteristics of easy processing. Such as in cranial bone repair, PEEK can achieve a high degree of compatibility with the patient’s skull after personalized design and processing. So that it can achieve an aesthetic effect and at the same time eliminate the psychological burden of the patient. This can achieve aesthetic effect and eliminate the psychological burden of patients, and improve the level of postoperative rehabilitation and quality of life of patients.

At present, PEEK products have been successfully applied to artificial spinal implants, artificial joints, bone repair products and so on.