Customization and process flow of metal powder injection molding

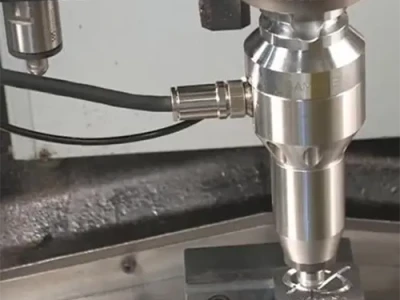

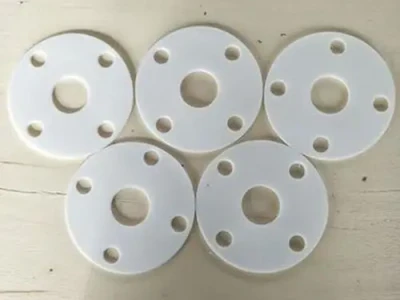

Brief Introduction to Customization and Technological Flow of Metal Powder Injection Molding (MIM) Products Metal powder injection molding is a process for making precision parts.We support metals of various complex shapes. Non-standard customization of spare parts. Send us the picture and sample, SUN-YEE tech factories can achieve fast customization. How to order from SUN-YEE The process of asking us to customize MIM products...